The Ultimate Guide to the Different Types of Industrial Robots

By The RobotsTrader Staff | February 11th, 2025

Why Industrial Robots Are Transforming Manufacturing

Industrial robots have become essential to modern manufacturing, boosting productivity and efficiency across countless industries. From assembly lines to warehouses, these robots handle tasks with precision, speed, and reliability.

If you’re exploring options for integrating robots into your operations—or just want to learn more about the industry—this guide breaks down the different types of industrial robots, including a deeper look at autonomous mobile robots (AMRs), humanoid robots, and other emerging technologies.

Watch: The 5 Types of Industrial Robots Explained

Industrial robots come in many shapes and functions, from articulated arms to high-speed delta robots. In this video, we break down the five main types of industrial robots, how they work, and where they’re used in automation.

Types of Industrial Robots

Industrial robots are classified based on their structure, functionality, and application. Below are the primary types, with an expanded focus on newer categories.

1. Articulated Robots

Articulated robots are the most common type of industrial robot. These robots have rotary joints, allowing them to move with flexibility and precision, much like a human arm. They are typically used in welding, assembly, and material handling applications.

Popular Brands:

- Fanuc (e.g., M-10iA series)

- ABB (e.g., IRB 6700 series)

- KUKA (e.g., KR QUANTEC series)

Key Benefits:

Can perform complex tasks

High degree of flexibility

Wide range of payload capacities

2. SCARA Robots (Selective Compliance Assembly Robot Arm)

SCARA robots are known for their speed and precision in pick-and-place tasks. They operate on a single plane, making them ideal for assembly lines and packaging operations.

Popular Brands:

Popular Brands:

- Fanuc (e.g., SR series)

- Yamaha (e.g., YK-XG series)

- Epson (e.g., LS series)

- Staubli (e.g., TS2 series)

Key Benefits:

- Fast and efficient for specific tasks

- Compact design

- Cost-effective for assembly operations

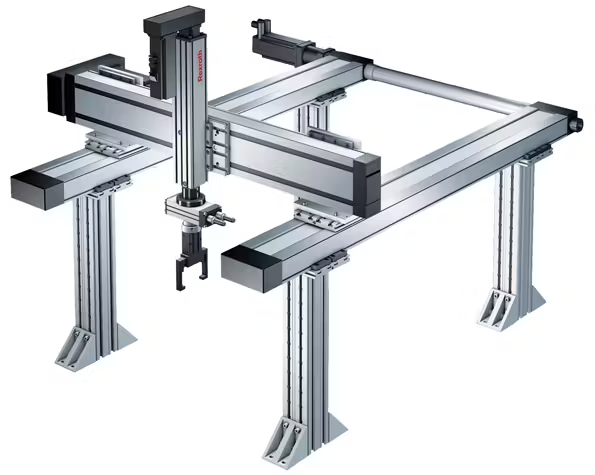

3. Cartesian Robots (Linear Robots)

Cartesian robots move along three linear axes: X, Y, and Z. These robots are highly accurate and often used in 3D printing, CNC machining, and assembly.

Popular Brands:

• IAI (e.g., RoboCylinder series)

• Bosch Rexroth (e.g., EasyHandling series)

• Parker Hannifin

Key Benefits:

• Simple design and programming

• High precision

• Cost-effective for applications requiring straight-line movements

4. Delta Robots (Parallel Robots)

Delta robots are lightweight and incredibly fast, making them perfect for food packaging and electronics assembly. Their unique design allows for high-speed movements with precision.

Popular Brands:

- Fanuc (e.g., M-2iA series)

- ABB (e.g., FlexPicker IRB 360)

- Omron (e.g., Adept Quattro)

Key Benefits:

- High-speed performance

- Lightweight construction

- Ideal for delicate operations

5. Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers, enhancing safety and efficiency. They are equipped with advanced sensors and software to ensure safe operation in close proximity to people.

Popular Brands:

- Fanuc (e.g., CRX series)

- Universal Robots (e.g., UR3e, UR5e)

- Rethink Robotics (e.g., Sawyer)

Key Benefits:

- Easy to program and deploy

- Increases safety in mixed human-robot environments

- Flexible and versatile for various tasks

6. Autonomous Mobile Robots (AMRs)

Autonomous mobile robots (AMRs) are self-navigating robots that use sensors and software to move independently within a workspace. AMRs are commonly used in warehouses for tasks like transporting goods or organizing inventory.

Popular Brands:

- MiR (Mobile Industrial Robots)

- Fetch Robotics

- Geek+

- Otto Motors

- Locus Robotics

Key Benefits:

- Adaptable to dynamic environments

- Reduces the need for fixed infrastructure like conveyor belts

- Boosts operational efficiency

7. A Future to Consider: Humanoid Robots

Humanoid robots represent an exciting frontier in robotics. While not widely adopted in industrial settings, these robots are designed to mimic human motion and behavior.

Popular Examples:

- Tesla’s Optimus

- Boston Dynamics’ Atlas

- SoftBank’s Pepper (customer-focused applications)

Potential Applications:

- Performing complex maintenance in industrial settings

- Assisting in customer service or retail operations

- Acting as flexible assistants in healthcare or hazardous environments

Although still developing, humanoid robots hold immense potential for future automation.

Why Consider Used Industrial Robots?

For companies looking to adopt automation on a budget, used industrial robots are an excellent option. They offer the same capabilities as new robots but at a fraction of the cost.

A marketplace like RobotsTrader.com connects reputable sellers with buyers, providing access to a wide range of pre-owned robots.

Advantages of Used Robots:

- Significant cost savings

- Faster ROI compared to new robots

- Reduced lead times for deployment

Key Considerations When Choosing an Industrial Robot

When selecting a robot for your operations, consider these factors:

- Application: Define tasks like assembly, packaging, or material handling.

- Payload Capacity: Ensure the robot can handle the weight of its items.

- Work Envelope: Consider the range of motion required.

- Integration Needs: Evaluate how the robot fits with existing systems.

Conclusion

Robotics technology continues to evolve, offering diverse automation solutions. Whether you need precision, adaptability, or innovation, choosing the right model is crucial.

For those exploring the best in robotics, RobotsTrader.com is a trusted resource offering a wide selection and expert insights. The future of robotics is here—find the perfect industrial robot today!

Explore Specific Types of Industrial Robots

This article is part of our Used Industrial Robots 101: Basics of Automation Series, where we break down different types of industrial robots and their applications. If you’re interested in learning about other robotic systems, check out these in-depth guides:

🔹 What Is an Articulated Robot? – Learn about articulated robots, their flexibility, and their role in automation.

🔹 What Is a Delta Robot? – Dive into delta robots, their high-speed design, components, and applications in automation.

🔹 What Is a SCARA Robot? – Discover SCARA robots, their high-speed precision, and cost-effective applications.

Leave a Reply