What Is a Delta Robot? A Complete Guide to Components, Programming, and Applications

Introduction

Going back to the basics again with another great guide in our Used Industrial Robots 101: Basics of Automation, Used Robots & Automation Guides Series.

Delta robots are a specialized type of industrial robot designed for high-speed, precision applications. Their parallel-arm kinematic structure enables rapid and accurate movement, making them ideal for tasks such as pick-and-place operations, packaging, and electronics assembly. Unlike articulated robots, which have serial-linked joints, delta robots have a fixed base with lightweight arms that move in unison, providing greater speed and efficiency.

This guide will cover:

- The key components of delta robots, including their motors, reducers, and controllers

- How delta robots are programmed, including coordinate systems and programming languages

- Industry applications and considerations for selecting the right delta robot

What Is a Delta Robot?

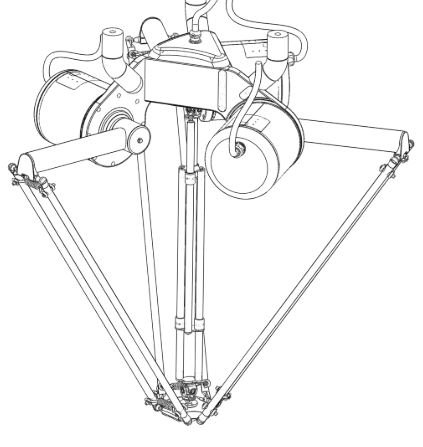

The Parallel Kinematic Structure

Delta robots feature a parallel-arm design, meaning multiple arms are connected to a shared platform. This structure allows for:

- High-speed operation – The arms are lightweight, and the motors are mounted at the base, reducing inertia

- Precision and stability – The arms move synchronously, ensuring accurate and repeatable positioning

- Energy efficiency – Only the arms and end effector move, reducing power consumption

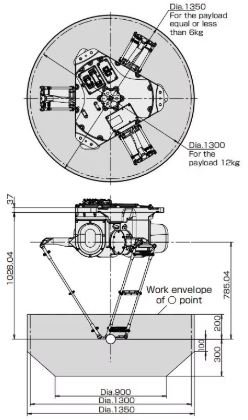

Key Features of Delta Robots

Delta robots are designed for high-throughput operations and offer several advantages over other industrial robots:

- Speed – Capable of performing more than 100 pick-and-place cycles per minute

- Compact design – The stationary base minimizes floor space requirements

- High precision – Sub-millimeter accuracy for delicate assembly tasks

Major Components of a Delta Robot

The Frame & Parallel Arms

The stationary base provides support, while the parallel arms—typically made from lightweight materials like carbon fiber—enable fast, stable movement.

Motors & Actuators

Most delta robots use servo motors mounted at the base. These motors drive the arms via belts or direct-drive actuators, ensuring rapid response times and precise positioning.

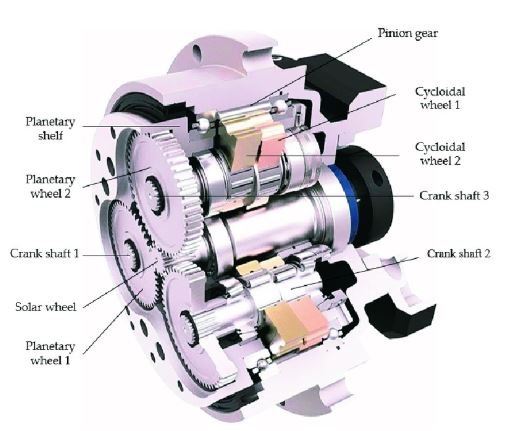

RV Reducers & Gear Systems

RV reducers (strain wave or cycloidal gears) are used to manage torque and motion control, allowing for smooth and controlled movement at high speeds.

Controller & Teach Pendant

The controller serves as the robot’s central processing unit, executing commands and integrating with automation systems. Teach pendants allow operators to manually program and adjust the robot’s settings.

Programming Delta Robots

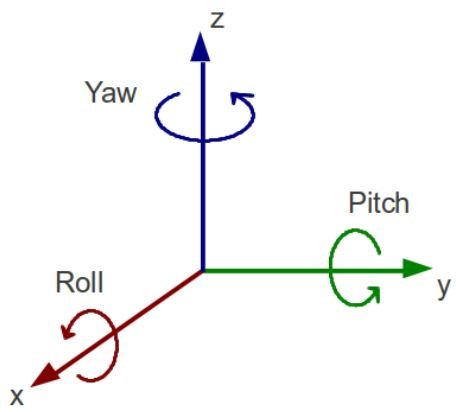

Coordinate Systems

Delta robots operate within a Cartesian coordinate system (X, Y, Z axes) and may also incorporate rotational movement. Their programming involves defining movement paths and pick-and-place points based on precise spatial coordinates.

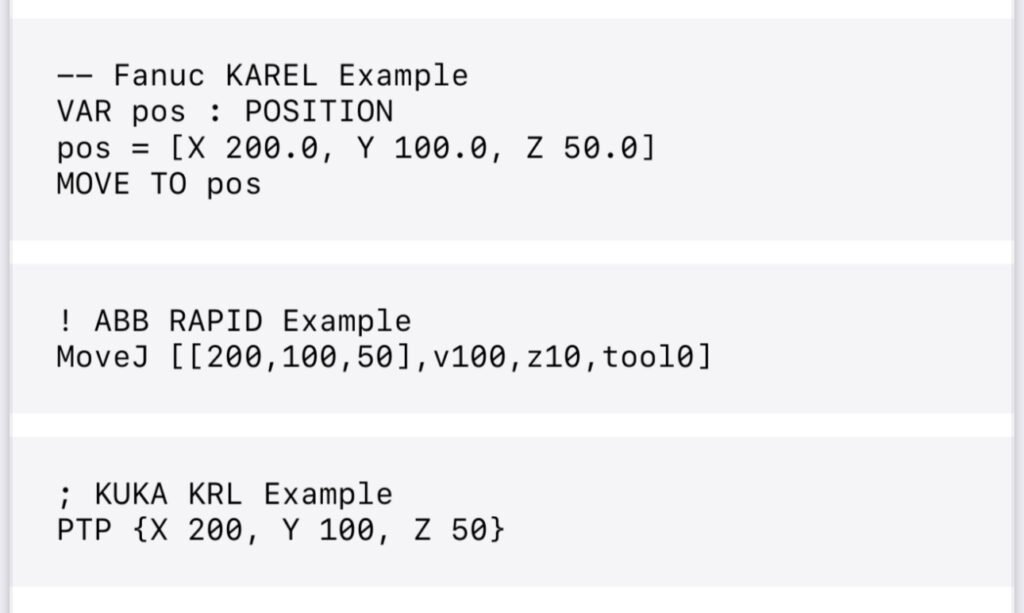

Common Programming Languages & Interfaces

Different manufacturers provide proprietary programming languages for delta robots:

- Fanuc – TP/Roboguide

- ABB – RAPID

- KUKA – KRL

Industry Applications of Delta Robots

High-Speed Pick-and-Place Operations

Delta robots are widely used in industries requiring rapid handling of small objects, including:

- Food and beverage packaging – Sorting and placing products on conveyor belts

- Electronics manufacturing – Handling delicate components with high precision

- Pharmaceutical automation – Dispensing and assembling medical products

Assembly & Packaging Automation

Delta robots are frequently integrated into automated assembly lines, where they assist in positioning, filling, and sealing products efficiently.

3D Printing & Specialized Applications

Some high-precision 3D printers and laser engraving machines utilize delta robot configurations for smooth and stable motion control.

Popular Brands & Models of Delta Robots

Several leading robotics manufacturers produce high-performance delta robots for industrial applications. Some of the most well-known brands and models include:

Fanuc Delta Robots

- Fanuc M-1iA – Compact, ideal for small part handling and electronics

- Fanuc M-2iA – Medium-sized with a larger workspace, often used in packaging

- Fanuc M-3iA – Large-scale delta robot for high-speed food and pharmaceutical applications

ABB Delta Robots

- ABB IRB 360 (FlexPicker) – One of the most widely used delta robots in pick-and-place automation, known for its precision and speed

- ABB IRB 390 (FlexPacker) – Designed for heavier payloads and high-speed packing applications

KUKA Delta Robots

- KUKA KR Delta – Stainless steel design ideal for hygienic environments like food and medical industries

Other Major Delta Robot Brands

- Staubli TP80 – A high-speed delta robot used in electronics and small-part assembly

- Codian Robotics D2 Series – Customizable delta robots designed for high-speed automation

Choosing the Right Delta Robot

When selecting a delta robot for industrial use, key factors to consider include:

- Payload capacity – The maximum weight the robot can handle

- Speed and cycle time – The required throughput for the application

- Programming compatibility – Integration with existing automation systems

- Vision system support – Ability to recognize and adjust to randomly positioned objects

Conclusion – Find Delta Robots for Sale on RobotsTrader.com

Delta robots have transformed modern manufacturing with their high-speed precision and efficiency. Whether used in food processing, electronics assembly, or pharmaceutical production, they provide unmatched performance in automation.

For those looking to purchase a delta robot, RobotsTrader.com is a leading marketplace for used and refurbished industrial robots from top manufacturers like Fanuc, ABB, and KUKA.

Explore More Types of Industrial Robots

This article is part of our Used Industrial Robots 101: Basics of Automation Series, where we break down different types of industrial robots and their applications. If you’re interested in learning about other robotic systems, check out these in-depth guides:

🔹 What Is an Articulated Robot? – Learn about articulated robots, their flexibility, and their role in automation.

🔹 What Is a SCARA Robot? – Discover SCARA robots, their high-speed precision, and cost-effective applications.

🔹 Ultimate Guide to the Different Types of Industrial Robots – Explore the full range of industrial robots, including SCARA, Cartesian, and collaborative robots.

Leave a Reply