What Is a SCARA Robot? A Complete Guide to Components, Programming, and Applications

Introduction

Going back to the basics again with another great guide in our Used Industrial Robots 101: Basics of Automation, Used Robots & Automation Guides Series.

What is a SCARA robot? SCARA robots (Selective Compliance Articulated Robot Arms) are widely used in industrial automation for high-speed, high-precision assembly, pick-and-place, and material-handling tasks. With a rigid vertical axis and flexible horizontal movement, SCARA robots excel in tasks requiring precise, repetitive motion. Additionally, SCARA robots are often more affordable than articulated robots, making them a cost-effective choice for applications that do not require the full range of motion provided by articulated designs.

This guide will cover:

- The key components of SCARA robots, including their motors, reducers, and controllers

- How SCARA robots are programmed, including coordinate systems and programming languages

- Industry applications and considerations for selecting the right SCARA robot

What Is a SCARA Robot? Understanding Its Design & Functionality

The Unique Four-Axis Design

SCARA robots are designed with a four-axis configuration, offering:

- High-speed movement – The lightweight arm moves swiftly and efficiently.

- Precision and stability – The rigid Z-axis provides vertical accuracy.

- Compact footprint – Ideal for confined workspaces and assembly lines.

- Affordability – A more budget-friendly alternative to articulated robots for suitable applications.

Key Features of SCARA Robots

SCARA robots provide several advantages over other industrial robot types:

- Fast cycle times – Ideal for high-speed automation

- Precision and repeatability – Sub-millimeter accuracy for intricate tasks

- Rigid vertical motion – Ensures stability during assembly and material handling

- Cost-effectiveness – A more affordable alternative to articulated robots when the application allows for it

Major Components of a SCARA Robot

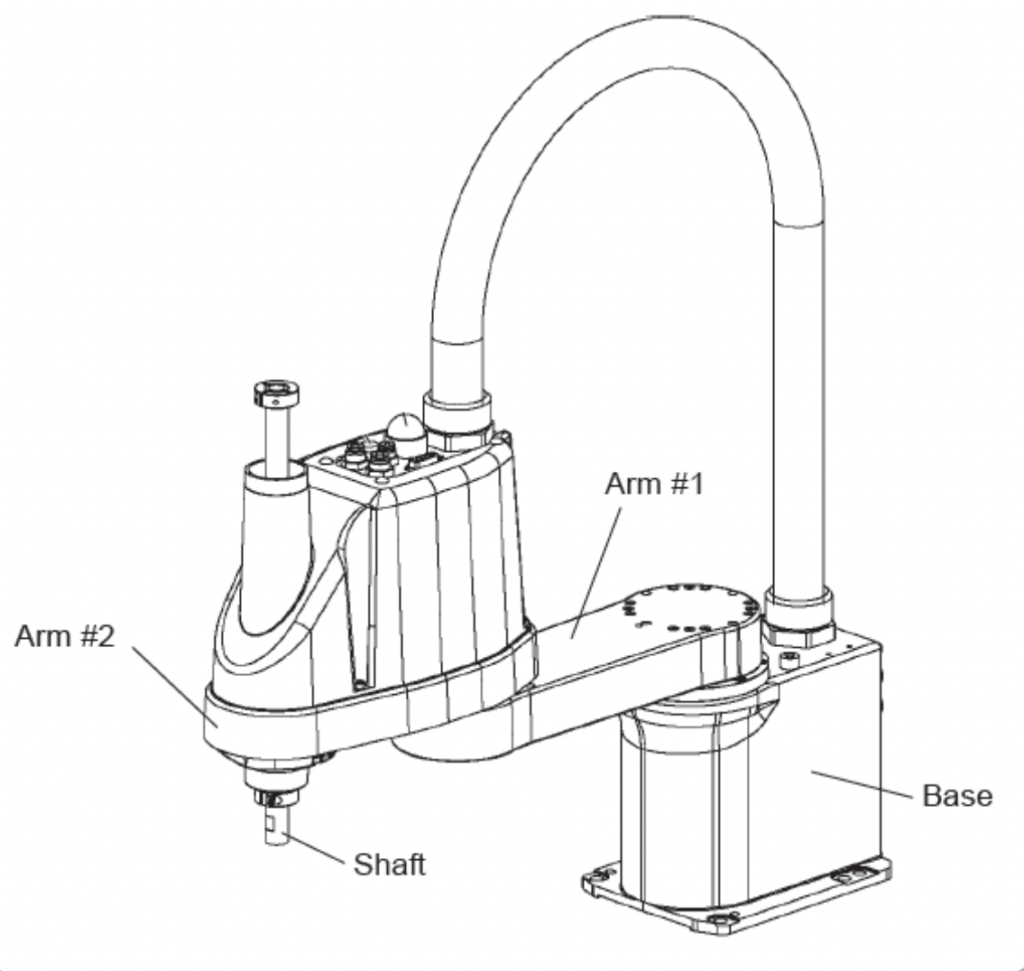

The Base & Arm Assembly

The fixed base houses the motors, while the horizontal arm consists of rotary joints for controlled movement.

Motors & Actuators

SCARA robots use servo motors to drive each joint, providing high torque and precise control over movement.

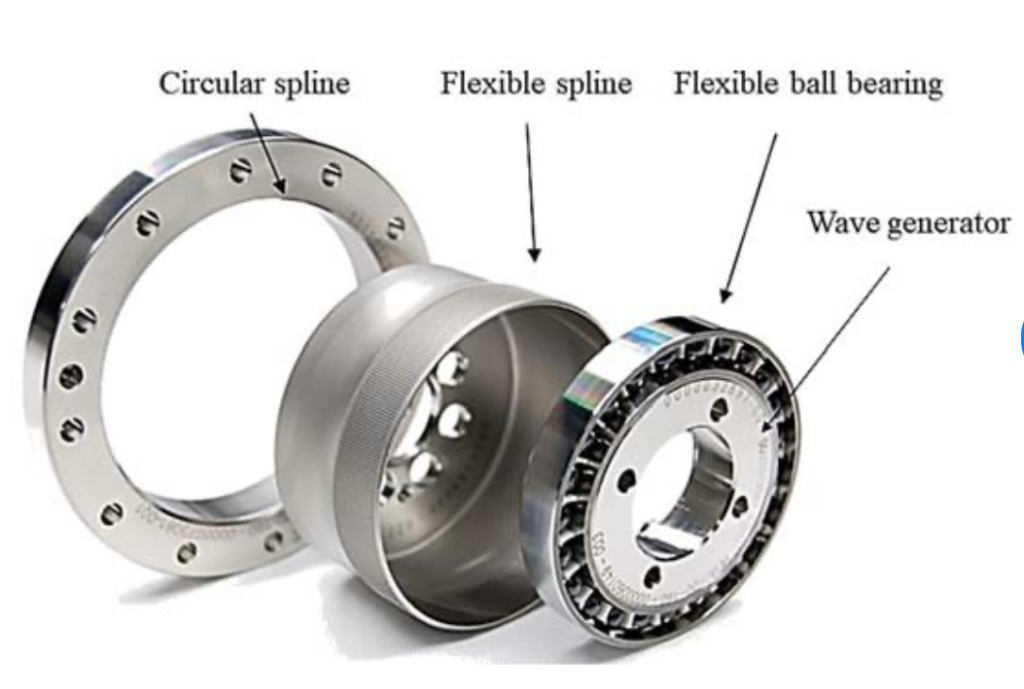

Gear Systems & Reducers

Harmonic drives and planetary gear reducers help manage torque and enable smooth motion control.

Controller & Teach Pendant

The robot controller acts as the brain, processing commands and integrating with automation systems. The teach pendant allows operators to program and adjust movement parameters manually.

Programming SCARA Robots

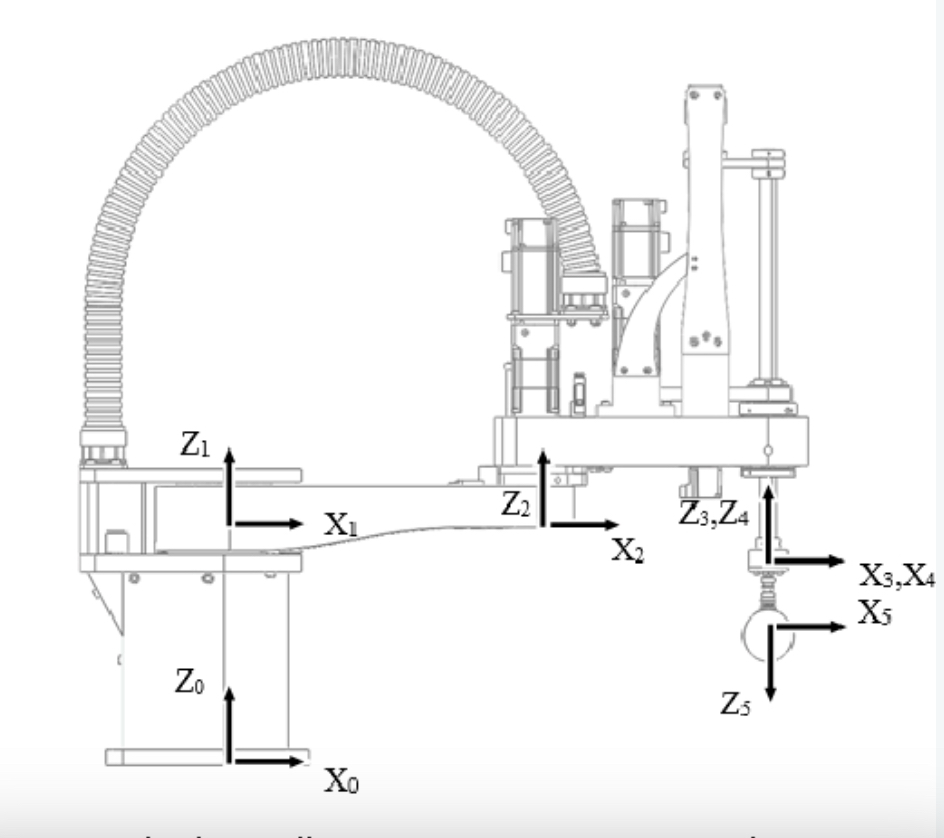

Coordinate Systems

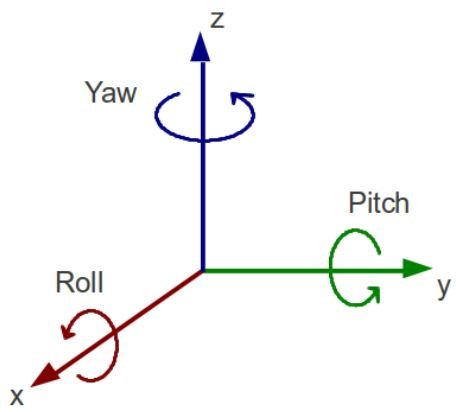

SCARA robots use a combination of Cartesian (X, Y, Z) and rotational movement, making them ideal for assembly and pick-and-place applications.

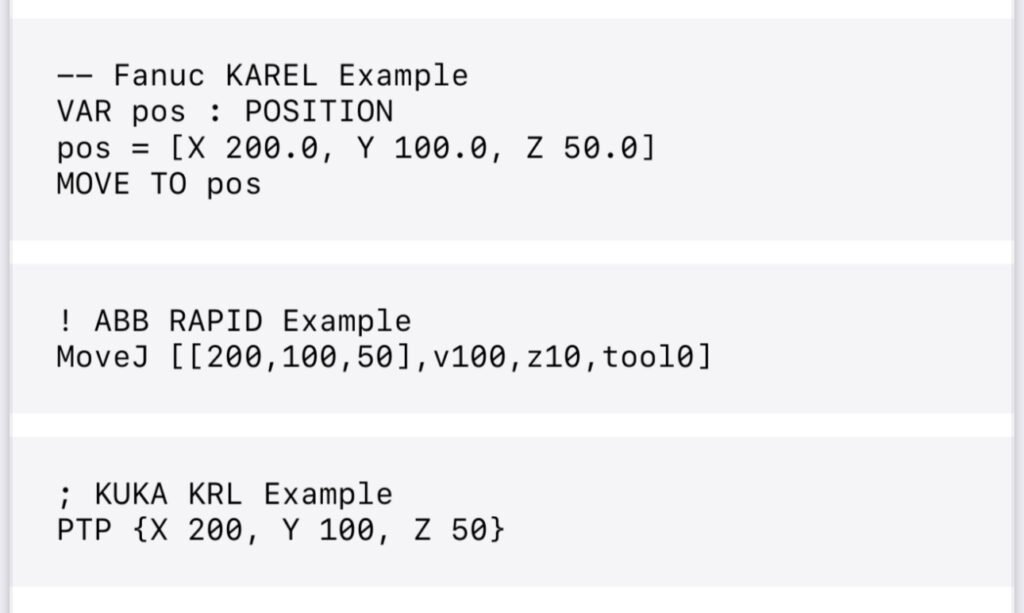

Common Programming Languages & Interfaces

Different manufacturers provide proprietary programming languages for SCARA robots:

- Fanuc – Karen

- ABB – RAPID

- Epson – SPEL+

- Mitsubishi – MELFA BASIC

Industry Applications of SCARA Robots

High-Speed Assembly & Pick-and-Place

SCARA robots are widely used in industries requiring fast, precise movement, such as:

- Electronics – Circuit board assembly and soldering

- Automotive – Component assembly and quality inspection

- Pharmaceutical – Dispensing and packaging of medical supplies

Packaging & Material Handling

SCARA robots are frequently integrated into packaging lines for tasks such as labeling, sorting, and case packing.

Popular Brands & Models of SCARA Robots

Several leading robotics manufacturers produce high-performance SCARA robots. Some well-known brands and models include:

Fanuc SCARA Robots

- Fanuc SR-3iA – Compact, ideal for small parts assembly

- Fanuc SR-12iA – Higher payload capacity for material handling

Epson SCARA Robots

- Epson T3 – Cost-effective SCARA robot for general automation

- Epson G-Series – High-speed, high-precision models for complex tasks

Mitsubishi SCARA Robots

- Mitsubishi RH Series – Versatile SCARA robots with advanced motion control

What Is the Best SCARA Robot for Your Application?

When selecting a SCARA robot for industrial use, key factors to consider include:

- Payload capacity – The maximum weight the robot can handle

- Speed and accuracy – Cycle time requirements and precision levels

- Integration capabilities – Compatibility with existing automation systems

- Footprint and workspace – Ensuring the robot fits within spatial constraints

- Budget – SCARA robots offer a cost-effective alternative to articulated robots in suitable applications

Conclusion – Find SCARA Robots for Sale on RobotsTrader.com

SCARA robots are a game-changer in modern manufacturing, offering speed, precision, and efficiency in automation. Whether for electronics assembly, material handling, or packaging, they are an essential tool for many industries. Their affordability compared to articulated robots makes them a great option for cost-conscious businesses needing reliable automation solutions.

If you’re looking to purchase a SCARA robot, RobotsTrader.com is a trusted marketplace for used and refurbished industrial robots from top manufacturers like Fanuc, Epson, and Mitsubishi.

This article is part of our Used Industrial Robots 101: Basics of Automation Series, where we explore different types of industrial robots and their applications. If you’re interested in learning about other robotic systems, check out these in-depth guides:

🔹 Ultimate Guide to the Different Types of Industrial Robots – Explore the full range of industrial robots, including SCARA, Cartesian, and collaborative robots.

🔹 What Is an Articulated Robot? – Learn about articulated robots, their flexibility, and their role in automation.

🔹 What Is a Delta Robot? A Complete Guide Dive into delta robots, their high-speed design, components, and applications in automation.

Leave a Reply